Differential interference contrast

Differential interference contrast (DIC) observation is a method of adding image contrast to micro topographic features in real time using optical interference. DIC observation does not require Z-scan or image processing and shows a superior detection capability even at low magnification, allowing you to search for the sample's damage and defects in a simple operation. If you try to look for micro topographic features using confocal observation, you need to use high magnification, but it makes the field of view small.

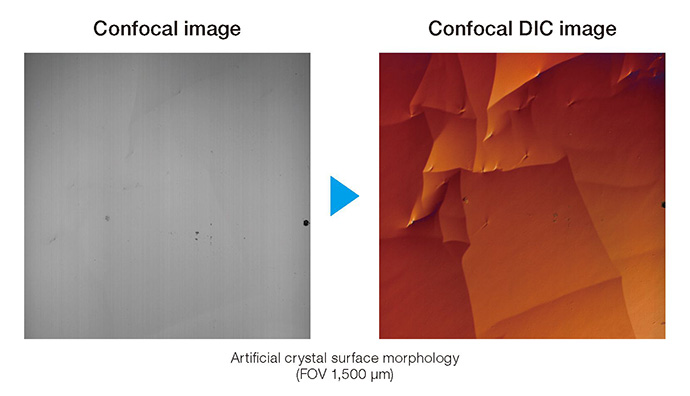

Since DIC observation and confocal observation are based on mutually independent operation principles, both of these capabilities can be used together to provide a combined result. Confocal observation makes the depth of focus shallow, and this allows DIC observation to visualize micro topographic features on the surface of a transparent material in a clear image free from the interference of reflected light from the back surface.

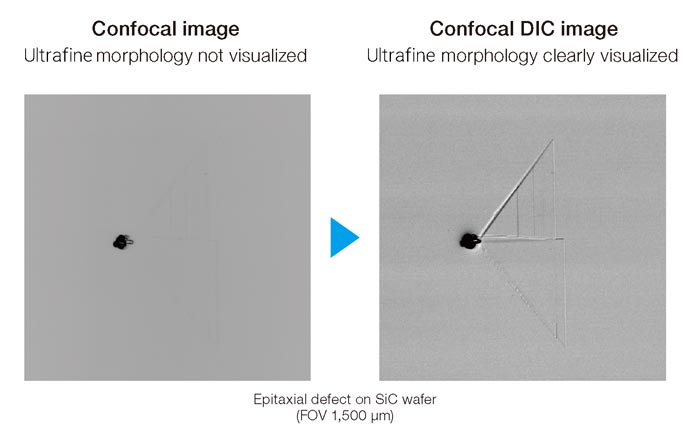

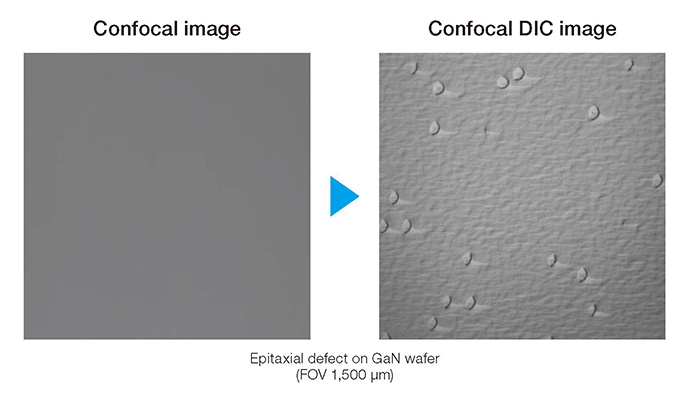

Examples are shown in the pictures below. In each of these examples, confocal observation alone cannot show ultrafine shapes on the surface. When DIC observation is added, however, the shapes become clearly visible. Ordinary DIC observation without confocal is not capable of distinguishing the back surface from the front surface for a transparent material. By adding confocal to DIC observation, we can make the depth of focus shallow and clearly capture the small surface topography. This is the great advantage of using confocal and DIC observation together. Unlike a DI lens, DIC observation uses the common optical path of HYBRID+ for interference, and it is less susceptible to the effect of vibration. Since DIC observation can be conducted with a large field of view, it is suitable for inspection applications that require the real-time observation of images.

Particle/defect inspection

DIC observation adds contrast to nanometer-scale topography and enables the real-time observation of surface roughness, scratches, and defects. It is especially useful for observing and qualifying SiC wafers.

Linking with auto inspection function

DIC is highly suitable for detecting small particles and surface defects. Because of its relative robustness against vibrations, it can be used with auto inspection software. Automated inspection will allow you to conduct whole-wafer inspection.

You might also be interested in