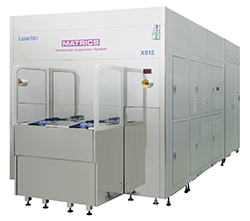

New Product: Mask Inspection System MATRICS X810 Series

2012.11.13

Mask inspection system for semiconductor devices at 20nm node and beyond

November 13, 2012 - Lasertec Corporation today announced MATRICS X810 series, a new line of high-speed mask inspection systems for semiconductor devices at the 20nm node and beyond.

Description

Lasertec has launched X810 series, the latest model of the MATRICS systems, offering remarkably improved inspection capability compared to the X700/X700HiT series. The X810 series has achieved superior defect detection sensitivity by featuring a new objective lens with higher-NA, a 50nm pixel size, a high power 213nm laser, and a new highly rigid stage.

Quality assurance of photomasks is very important to achieve high yield in semiconductor device production. Periodic inspection of masks is indispensable for detection of "haze" (chemically grown particles by DUV exposure), which remains an unsolved problem for wafer fabs using ArF lithography. Furthermore, as finer design rules are applied to IC patterns, more frequent inspections of photomasks will be required. EUV masks require high-sensitivity inspections at even shorter intervals because pellicles cannot be used to keep particles and contamination away from pattern surfaces. Therefore, mask inspection systems must be able to perform high-sensitivity inspection at a very high speed. MATRICS X810 series has been developed to meet this requirement, making it an effective inspection tool for leading-edge wafer fabs and mask shops.

Lasertec has a long history and can draw on a high level of technical expertise in the field of semiconductor photomask inspection. Lasertec developed the world's first photomask inspection system in 1976. The current MATRICS X700/X700HiT series has been widely adopted by wafer fabs and mask shops in Japan, Korea, Taiwan, Germany, the United States and China for its high sensitivity, high availability, and low cost of ownership.

Key Features

- High-sensitivity and high-speed mask inspection system designed for 20nm technology node and beyond

- Newly-designed high NA objective lens, a pixel size of 50nm, a high power 213nm QCW laser (200mW), and a highly rigid stage

- Autoloader for RSP150 and RSP200 for photomasks and dual pods for EUV masks

- Full-automatic inspection linked with overhead hoist transport (OHT)

- Compact all-in-one design with power supply and control unit embedded in the main body (W: 2400mm x L: 3850mm x H: 2440mm)

Applications

- Incoming and periodic quality assurance inspection of photomasks and EUV masks at wafer fabs

- Outgoing inspection of photomasks and EUV masks at mask shops