Supply Chain Initiatives

Basic Policy of Procurement

Lasertec is guided by its corporate philosophy since its foundation, "Inventing for your success, inventing for the future", and our vision to "Be the most reliable partner for customers worldwide".

Based on these, we adopt a fab-lite strategy, under which we outsource the production of our products to third parties so that we can provide customers with solutions faster than anyone else.

Today, we face various social issues, including environmental and human rights concerns. We believe that to foster a prosperous and sustainable society, it is essential that we, along with our suppliers, not only ensure the quality and performance of our products but also engage in environmental, social, and governance (ESG) initiatives. By strengthening our relationships with them through these initiatives, we aim to create a sustainable supply chain.

Under such circumstances, together with the growing demand for sustainability management, we are expected to reduce ESG risks across the entire supply chain and enhance supply chain agility and resilience. It is our basic policy that we practice fair business, and we strive to create value in the supply chain by building relationships based on trust with our suppliers who support our business and engage in co-creation with them.

Sustainable Procurement Policy

In our everyday procurement activities, we promote open communication with our suppliers and build relationships with them based on trust and co-creation. We hope to grow together with them while fostering an ethical and sustainable society.

We go beyond compliance with the laws, regulations, and social norms of the countries where we operate and engage in procurement initiatives that conform to international standards and guidelines to meet stakeholder expectations. Our code of conduct aligns with the RBA Code of Conduct compiled by the Responsible Business Alliance (RBA), and we ask our suppliers to adhere to the same Code of Conduct. We believe that by doing so, we can create products that meet our customers' needs with all materials and components conforming to their respective specifications and quality standards.

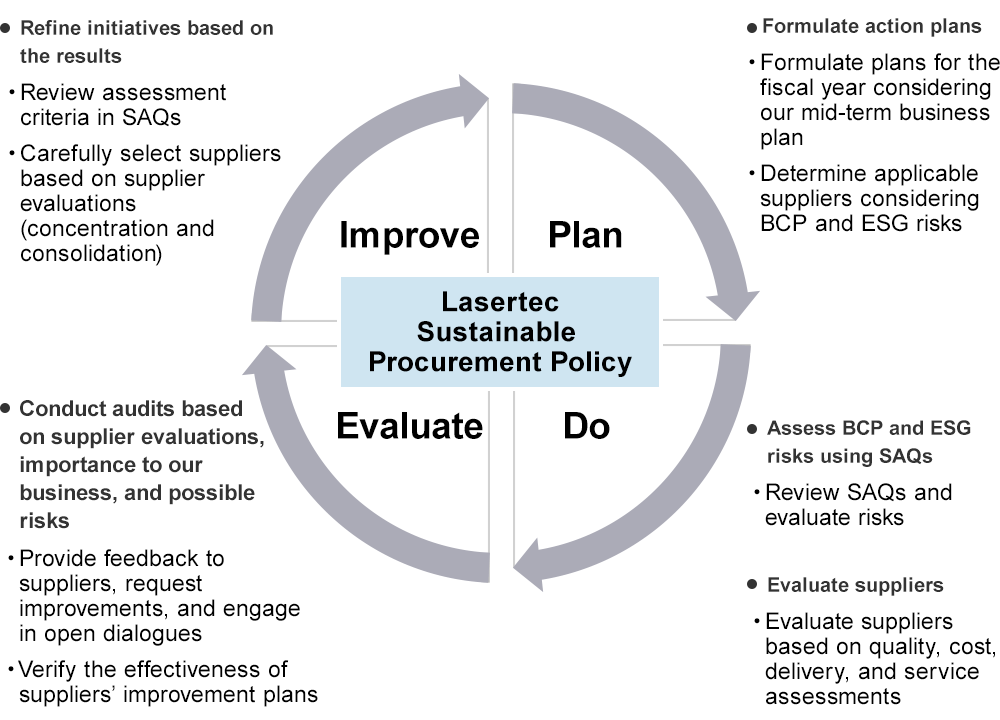

We monitor the status of suppliers' initiatives with respect to our Sustainable Procurement Policy by performing supplier evaluations, asking suppliers to answer various questionnaires, including self-assessment questionnaires ("SAQs"), and conducting audits. We request suppliers to make improvements when necessary, monitor their progress in implementing such improvements, and verify their effectiveness. In this activity, we value open and meaningful dialogues with our suppliers and support their improvement efforts as needed.

| Initiatives | |

|---|---|

| Declaration of Partnership Building | Seek coexistence and coprosperity across the entire supply chain. |

| QCDS (Quality, Cost, Delivery, and Service) | Engage in procurement activities that ensure appropriate quality, pricing, and delivery based on prior agreements with suppliers. This includes providing Key Suppliers with feedback based on their annual QCDS assessments and requesting improvements. |

| Human Rights | Engage in procurement activities that are conscious of human rights, work environments, and worker health and safety. |

| Environment | Engage in environmentally conscious procurement activities that focus on reducing environmental burdens in the supply chain. |

| Business Continuity Planning (BCP) | Prepare for unforeseen events by formulating a business continuity plan and promoting activities that enhance supply chain resilience. |

| Information Security and Cyber Security | Strictly manage confidential information obtained during the course of business. Consult with suppliers about their countermeasures against malicious third-party attacks and, if necessary, provide support as needed to prevent negative impacts on production activities and the entire supply chain. |

| Conflict Minerals | Promote responsible procurement of minerals throughout the entire supply chain. |

| Supplier SAQs and Audits | Ask suppliers to complete SAQs about their compliance with our Sustainable Procurement Policy, BCP, and design change management, and, if necessary, conduct on-site audits and interviews to verify their situations. Provide feedback, request improvements, and verify the effectiveness of corrective actions. |

Sustainable Procurement Guidelines

These guidelines set out our views on sustainable procurement and our requests to suppliers. They are based on the RBA Code of Conduct and internationally recognized standards, as well as the expectations of society and our stakeholders.

Green Procurement Guidelines

These guidelines set out our views on green procurement and our specific requests to suppliers, based on our Sustainable Procurement Guidelines.

Note:

We designate our suppliers whose transactions with us account for the top 80% of our annual spend, as well as staffing agencies and on-site subcontractors, as "Key Suppliers". The Supplier Program described on this page applies to our Key Suppliers.

Request for Compliance with Our Sustainable Procurement Policy

We request our suppliers to agree in writing to comply with our Sustainable Procurement Policy to ensure their awareness and concurrence.

We are striving to be a good corporate citizen that complies with laws and social norms around the world and to be a company that meets our customers' expectations. In this context, we conduct surveys and regularly hold briefings for suppliers to strengthen our supply chain and promote understanding of our initiatives. We communicate our respective responsibilities to our suppliers and engage in open, meaningful dialogue to build a true partnership with them based on mutual understanding and trust.

Supplier Program

We adopt a fab-lite strategy where the production of most systems is outsourced to third parties. We therefore consider it essential to build and strengthen genuine partnerships based on co-creation with each of our suppliers. To meet the expectations of society and our stakeholders, we have established a supplier program aligned with international standards including the Ten Principles of the UN Global Compact, the OECD Guidelines for Multinational Enterprises, and the ILO's Fundamental Conventions (Core Labour Standards).

Lasertec's Initiatives

We select our suppliers, including manufacturing contractors, with the aim of creating true partnerships that drive mutual business growth through the co-creation of world-first, cutting-edge products. For Key Suppliers, we implement supplier management initiatives and review the contents of these initiatives as needed to enhance our relationships with them.

Starting July 2025, we have been revising the criteria of our supplier evaluation as well as the contents of SAQs, including their categories, questions, and scoring methodology, to further strengthen our supplier management.

Initiatives

Supplier Evaluation

We conduct an annual evaluation of Key Suppliers in the areas of quality, cost, delivery, and service, and provide feedback on the results. The purpose of this is to strengthen a sustainable supply chain and enhance our partnerships with suppliers by working together to identify and resolve issues.

Sustainable Procurement Policy SAQ

We ask each of our Key Suppliers to answer SAQs to assess their compliance with our Sustainable Procurement Policy. The purpose of this is to raise the level of our procurement to meet international standards and the expectations of society and our stakeholders. We use the results of the SAQs to identify transaction risks and make decisions about which suppliers to continue doing business with. We also visit their HQs and production facilities to audit their internal regulations, documents, and business records to verify their responses. We provide feedback on the results of audits and request improvements, if necessary. We ask them to submit an improvement plan and check the effectiveness of their efforts. We also communicate the need to strengthen their initiatives related to our Sustainable Procurement Policy.

BCP and Design Change Management SAQs

We believe it is important to strengthen our collaborative efforts with suppliers in the areas of business continuity planning (BCP) and design change management. We are taking specific measures to enhance the resilience and agility of our supply chain against contingency situations. We ask our suppliers to answer SAQs on BCP and design change management in the same manner as we do with our SAQs on compliance with our Sustainable Procurement Policy. The purpose of this is to determine whether the measures suppliers are taking meet the required standards and, if necessary, to request improvements. We provide feedback on the results and make requests for improvement. We ask them to submit an improvement plan and check the effectiveness of their efforts. We also communicate the need to strengthen their response capabilities related to BCP and design change management.

Supplier Audits

We audit suppliers regarding their responses on the Sustainable Procurement Policy, BCP, and design change management SAQs. We interview the managers of their supply chain-related departments and visit their production facilities to see if they comply with relevant regulations and standards. We also check their internal rules and records of actions to see if there is any discrepancy. This allows us to grasp the status of their activities that we would otherwise not be able to understand merely by conducting SAQs.

Creditworthiness Checks

We ask suppliers to disclose their business strategies and information about the status of their business, including their financial statements, when we start or renew business relationships with them in order to accurately understand their business conditions. We also check credit reports from research companies when necessary.

Schedule

In every fiscal year, we undertake various activities as part of our supplier program to enhance our supply chain and strengthen our partnerships with suppliers.

| What we do | How often | |

|---|---|---|

| Supplier evaluation | ■QCDS assessments ■Deciding content of next supplier evaluation |

Once a year |

| Sustainable procurement assessment | ■Supplier briefings | Once a year |

| ■Sustainable procurement Policy, Design change, and BCP SAQs ■Audits ■Feedback, requests for improvement and receiving improvement plans, verifying progress, and assessing effectiveness |

Once or twice a year1 | |

| Strengthening resilience | ■Credit checks | Once a year |

| Employee training | ■Training for new employees | Once a year |

| ■E-learning | As required |

Future Areas of Focus

In addition to the initiatives above, we are focusing on the following areas to further enhance our supply chain and strengthen our partnerships with suppliers.

| Initiative | Example Targets | |

|---|---|---|

| BCP | Map production locations | ・Conduct assessments of the production locations of Key Suppliers ・Enhance communication with Key Suppliers and tier 2 suppliers |

| Work together to address supply chain challenges | ・Reduce lead times by improving production processes ・Take on component procurement issues together as part of efforts to strengthen the supply chain |

|

| Communication | Build strong partnerships with suppliers | ・Hold briefings for suppliers to discuss our initiatives and requests for important matters such as our Sustainable Procurement Policy, BCP, and design changes |

| SAQs and audits | Make improvements based on the previous year’s activities | ・Revise SAQs so we can more accurately understand and evaluate the status of Key Suppliers |

| Careful selection of suppliers | Enter basic transaction agreements and request suppliers to consent to our guidelines | ・Execute a basic transaction agreement with suppliers, and request them to consent to our Sustainable Procurement Policy |

| Clarify with suppliers the areas identified for improvement in their supplier assessments and audits and provide feedback. | ・Support suppliers to achieve a high benchmark through our improvement activities ・Find new suppliers who consent to our Sustainable Procurement Policy |

| FY2025 Initiatives | Results | |

|---|---|---|

| BCP | ■Prepare for unforeseen events such as natural disasters ■Audit the production locations of each of the components we use |

Production or delivery delays: 0 Locations audited: 85% |

| Communication | ■Requested Key Suppliers to conduct due diligence on responsible mineral procurement at a supplier briefing. | Due diligence results received: 100% |

| SAQs and audits | ■Request suppliers to complete SAQs ■Provide feedback from SAQs, conduct on-site audits, and request improvements ■Request new suppliers to consent to our Sustainable Procurement Policy and complete SAQs |

Response rate: 95% Issues reported for improvement: 100% Suppliers consenting: 100% |

| Careful selection of suppliers | ■Ask suppliers to consent to our Sustainable Procurement Policy | Suppliers consenting: 90% |

Supplier Assessment

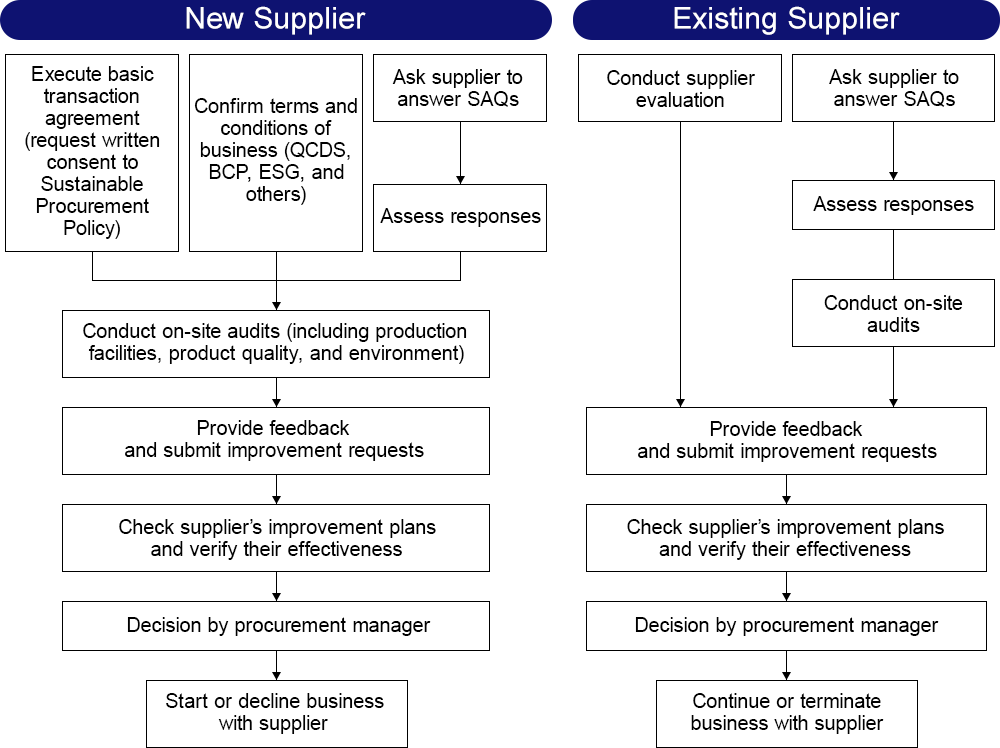

1) New Suppliers

Before conducting business with any new suppliers, we enter into a basic transaction agreement with them and, if necessary, request their written consent to our Sustainable Procurement Policy.

In some cases, we may ask them to confirm the terms and conditions of business (progress of QCD, BCP, ESG, and other initiatives) and/or conduct on-site visits to verify their activities.

2) Existing Suppliers

We keep suppliers informed about our procurement-related initiatives and request them to answer SAQs on their CSR procurement activities. If we find that improvement is necessary, we request that they submit an improvement plan and work together to address the issues. We conduct on-site audits to understand suppliers' situations and then follow it up to keep checking their compliance with our requests for improvement.

Communication with Suppliers

Declaration of Partnership Building

We have formulated a "Declaration of Partnership Building"2 and announced it publicly to promote the creation of new value throughout the entire supply chain while adhering to social norms by building better relationships with our business partners and furthering our healthy trade practices.

- 2The "Declaration of Partnership Building" was established at the "Council on Promoting Partnership Building for Cultivating the Future", whose members are comprised of the Chairman of the Japan Business Federation, the Chairman of the Japan Chamber of Commerce and Industry, the President of the Japanese Trade Union Confederation, and the ministers of relevant ministries (Cabinet Office, Ministry of Economy, Trade and Industry, Ministry of Health, Labour and Welfare, Ministry of Agriculture, Forestry and Fisheries, and Ministry of Land, Infrastructure, Transport and Tourism). The declaration is intended to show the determination to build a new type of partnership by promoting cooperation, coexistence, and coprosperity among partners in the supply chain and others seeking value creation.

Compliance Helpline for Business Partners

For the prevention, early detection, and swift resolution of compliance issues, we have put in place a compliance helpline for our suppliers, subcontractors, and other business partners. If you find any violation or potential violation of laws and regulations regarding our business practices, or the conduct of our officers and employees, please use this helpline to submit your report from the following website.

URL: https://www.dial-soudan.jp/cp/lasertec/login?lang=en

ID:lasertec Password:lasertec1960

- Notes about the helpline:

- This helpline is not for making business inquiries. If you have such an inquiry, please contact the department in charge.

- We will not treat whistleblowers or their employer companies unfavorably for their whistleblowing reports.

- All information contained in your whistleblowing report, including personal information, will be used only by our officers and employees responsible for handling compliance matters and only to the extent necessary to respond to the reports. We will not disclose such information to any third party without your prior consent unless we are required to do so by law. For information about the handling of personal information, please see our privacy policy.

- This helpline is a third-party-operated system with strict security control, available 24 hours a day, 365 days a year. You can submit reports either in Japanese or English, anonymously if you choose to do so.