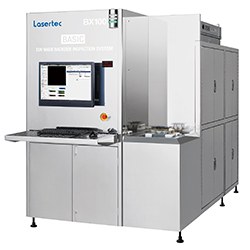

New Product: "BASIC Series" EUV Mask Backside Inspection and Cleaning System

2013.02.22

Integrated solution for detection, height measurement and cleaning of particles on the backside of EUV masks

February 22, 2013 - Lasertec Corporation announced today that it has launched a new product line called "BASIC Series" for inspection, measurement and cleaning of the backside of EUV masks.

(BASIC is an acronym of the backside inspection and cleaning system.)

Description

Extreme ultraviolet (EUV) lithography is a next-generation technology being developed for further scaling of integrated circuits. Pattern exposure using EUV scanner, unlike the conventional method, requires an electrostatic chuck to hold a mask. If particles are present on the mask's backside, to which the electrostatic chuck of EUV scanner is clamped, they will deform the mask substrate. This may result in misalignment of mask patterns during exposure. It is therefore necessary to keep the mask's backside clean and the chuck free from particles for a reliable EUV exposure process.

The new BASIC Series is designed to address such a need, and it offers the following functions:

1) Particle detection function based on optics that is optimized for detection of particles on the backside of EUV masks.

2) Particle height measurement function based on confocal optics for identification of particles that cause errors during exposure (killer particles), and

3) Cleaning function for removal of particles on the backside of EUV masks.

The BASIC Series also uses a dual pod handling system that has no risk of either particle adders or pattern surface damages.

Periodic inspections of EUV masks using the BASIC Series in the development phase of EUV mask handling sequences and onward can help ensure cleanliness of the backside of EUV masks. Lasertec recommends that wafer fabs, mask shops, and mask blank manufacturers take advantage of the BASIC Series for quality control of EUV masks.

Lasertec has a long history and a high level of technical expertise in the field of semiconductor photomask inspection. Lasertec developed the world's first photomask inspection system in 1976. The current models of MATRICS mask inspection systems and MAGICS mask blank inspection systems have been widely used among wafer fabs, mask shops, and mask blank manufacturers in Japan, Korea, Taiwan, Germany, the United States and China for its high sensitivity, high availability, and low cost of ownership.

Key Features

- Inspection optics optimized for detection of particles on the backside of EUV masks

- Measurement of the height of killer particles

- Cleaning function for removal of killer particles

- Dual pod handling system with no particle adders

- Scanning system that causes no pattern surface damages

- Inspection time that meets the requirement of EUV lithography in production

- Automatic inspection linked with overhead hoist transport

- Compact and all-in-one design including power supply and control unit

Applications

- Incoming and periodic inspection of EUV masks at wafer fabs

- Detection, height measurement, and cleaning of particles on the backside of EUV masks

- Outgoing inspection by EUV mask shops and mask blank manufacturers