White light confocal

A white light confocal microscope is a microscope that uses confocal optics and a white light souce. HYBRID+ can be used as a white light confocal microscope to perform full-color high-definition observation and high-resolution 3D profile measurement. This function has the following 4 features:

1. Full-color confocal observation

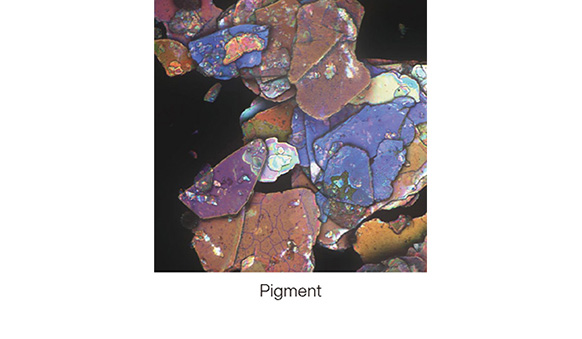

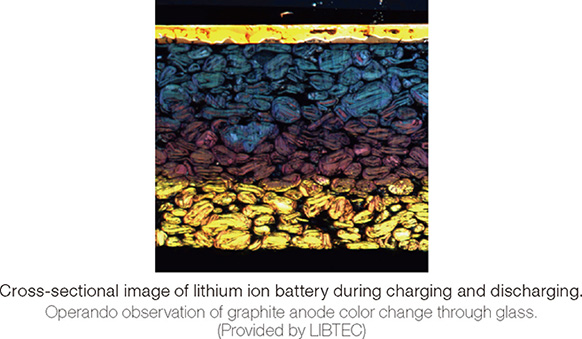

HYBRID+ uses a white light source that emits a beam whose spectrum closely resembles that of the sun light. It captures 24-bit high-definition full-color confocal images with long depth of focus. These images are useful for various observation purposes because they contain a large volume of information compared with monochromatic images.

As shown in the pictures below, full-color confocal observation captures the micro topographic features of powder foundation. It also provides a clear full-color image in the operando observation of a lithium ion battery even though the sample is observed through a glass window.

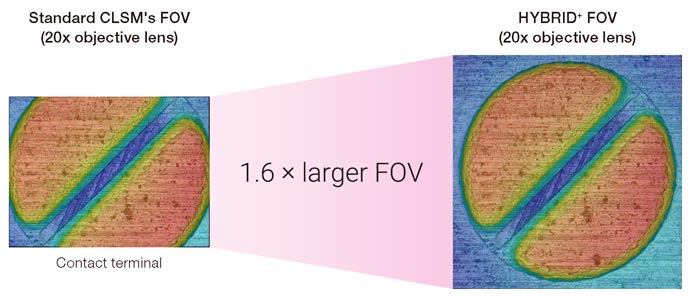

2. Observation/measurement with a wide field of view

HYBRID+ uses Lasertec-original white light confocal optics. They provide a field of view approximately 1.6-times larger than that of other ordinary laser microscopes when an objective lens of the same magnification is used.

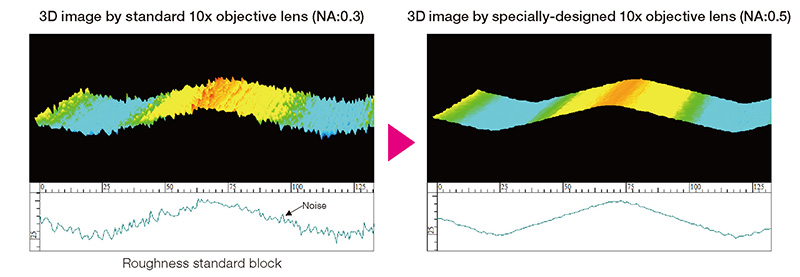

3. High precision measurement at low magnification

HYBRID+ enables highly precise measurement at low magnification based on a combination of its unique optics and specially-designed low-magnification high-NA lenses. This is a capability unmatched by other ordinary laser microscopes. Both of the images below are captured at the same 10x magnification but with different NA values. The one on the left, with NA 0.3, has noise in slope areas. The one on the right, with NA 0.5, shows significantly less noise and makes it possible to perform measurement with higher precision.

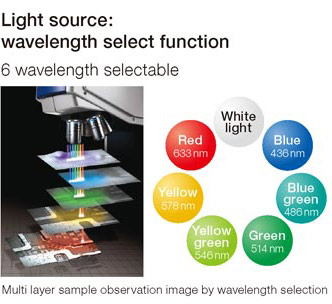

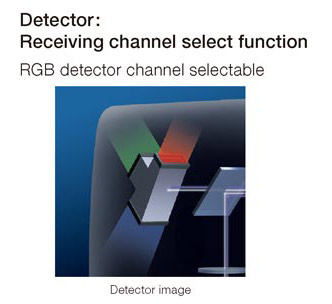

4. Wavelength selection

HYBRID+ offers multiple wavelengths of light to choose from so that users can conduct observation and measurement with an optimal wavelength for their purposes. The selection of wavelength can be made simply by changing the settings of light source wavelength and photodetector channel. Because of this capability, HYBRID+ can perform measurement on samples that are unsuitable for measurement with a fixed wavelength of light such as laser light.

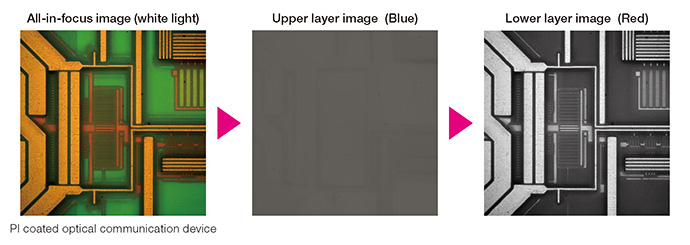

A sample absorbing a specific wavelength of light

There may be a case when your sample absorbs a certain wevelength of light. The absorption properties of insulators used for electronic circuit boards tend to differ from supplier to supplier. The properties may also change as coating thickness changes. For example, polyimide films are opaque to blue light, and if you select the channel of blue light, you will only capture their surface information. If you switch it to red light, which penetrates the films, you will be able to observe patterns underneath them.

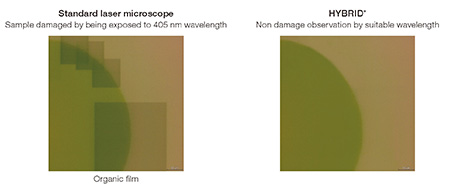

A sample that will be damaged by laser light

You may have a sample that chages its properties when exposed to a certain wavelength of light. Examples of such a sample are photoresists, UV-activated resins, and organic films. In such a case, you can avoid damage to your sample by selecting an optimal wavelength for observation or measurement. The pictures shown here are those of organic films. The left picture is a result of observation using 405nm laser light. You see an area where laser scan has caused damage on the sample's photo sensitivity. The picture on the right is a result of white light observation. Unlike the observation with laser light, you have no damage here. This enables you to achieve truly non-destructive observation.

Other applications

- Measurement of GaN defects on Si substrate

- You may have a sample with surface coating, such as one with insulation or protective coating. Such a sample tends to form an interference pattern as incident light hits the coating, and this may make it difficult to perform accurate profile measurement. If you use the broad spectrum of white light, it will help reduce the interference occurring inside the coating and allow you to perform accurate profile measurement.

You might also be interested in